Thursday, September 29, 2005

Thursday, September 22, 2005

Monday, September 19, 2005

Base stone has been installed in all three tanks. Also, all three tanks have been backfilled.

Posted by Picasa

Thursday, September 15, 2005

Monday, September 12, 2005

Thursday, September 08, 2005

Pottsville Republican Newspaper Article

SHEPPTON — A $2 million mine drainage treatment system in development could someday turn the Catawissa Creek into a world-class trout stream. "And we're hoping to have the project completed by November," said Thomas J. Davidock, a natural resources specialist with the Schuylkill Conservation District, Pottsville.

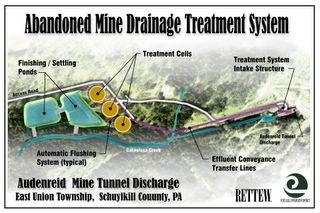

The system is being constructed to treat water flowing from the Audenreid Mine Tunnel, about two miles east of Sheppton. Earthmovers and contractors, including James T. O'Hara Inc., Moscow, Pa., have been hard at work at the site since March. "We have about 13,500 tons of limestone coming to the site," said Clayton E. Bubeck, project manager with RETTEW Associates Inc., Pottsville. "We're about two-thirds of the way through the project. Hopefully, before winter we'll see how this system works, be able to tweak it and get it ready to operate." "And by the spring trout season," Bubeck added, "we should see a definite improvement in the Catawissa Creek." The project was initiated in 2001 by the conservation district and the Catawissa Creek Restoration Association. But today, a dozen or more project partners are involved. Representatives from some of these groups met at the construction site Wednesday for a progress report and tour. The Audenreid discharge is the largest discharge in the Catawissa Creek Watershed, with an average flow of 8,478 gallons per minute. And because of it, the Catawissa Creek is on the state Department of Environmental Protection (DEP) list of impaired waterways. According to the plans, water from the tunnel will flow into a treatment system intake structure instead of directly into Catawissa Creek. From there it will be piped to three concrete, circular treatment cells. Each are 120 feet in diameter and 12 feet deep and will be filled with 4,600 tons of limestone. These cells were constructed and installed by Halteman Construction, Lebanon. The acidic water will go in with a pH level of about 4.03. Once treated, the pH will be at 7, or neutral. Called "an innovative passive treatment system," it will utilize new technology to treat the high rate of discharge, and it won't require much in the way of manpower. "The system must be flushed extensively and frequently in order to manage the accumulation of aluminum hydroxide solids and keep them out of the stream," Davidock said. "About every hour and a half, the treatment tanks will be automatically flushed by a series of automatic siphons into a large settling pond to receive the aluminum precipitate. The water will then flow into a second settling pond to provide final polishing before it is returned to the creek." Siphons that can be triggered automatically will keep the treatment cells from overflowing, said James M. Gotta, a member of the Catawissa Creek Restoration Association board of directors. "It does make it so that we don't have to have a manual operation," Gotta said. One obstacle the contractors faced was an underground gas pipe. "Right where we're standing, there's a high-pressure gas line under our feet," Bubeck said from a vantage point a stone's throw east of the treatment cells. "So far, Sunoco Pipeline Co. has been excellent to work with." The land the mine tunnel and treatment system is on is owned by Butler Enterprises, Hazleton. It's currently leased to Paragon Adventure Park and is used by all-terrain vehicles (ATVs) and off-road motorcycles. But Butler Enterprises has given this project the right-of-way on eight acres. In September 2004, the project received a $1.4 million grant from DEP through the Environmental Protection Agency (EPA) Federal Clean Water Act Section 319 Non-Point-Source Pollution Program. Other funding sources included a $150,000 grant from the federal Office of Surface Mining and a $100,000 grant from the state Bureau for Abandoned Mine Reclamation. "Coming up with funding for this project was a challenging feat, because it is the most expensive treatment system that was put on the ground in Pennsylvania for passive treatment," Davidock said. There are a large list of project partners, which include Eastern PA Coalition for Abandoned Mine Reclamation, Luzerne Conservation District, the Schuylkill County commissioners, East Union Township and Blue Knob Rod & Gun Club. "Project partners have really pulled everything together to get this thing off the ground," Davidock said. "I'm just in awe of all the work that's being done here," said Frederick L. Suffian, an EPA program manager based in Philadelphia. "We provide funding. We hope we get it to the right people and the right place. And this is an excellent example of doing just that."

©The REPUBLICAN & Herald 2005

Hazleton Standard Speaker Article

09/08/05

By KENT JACKSON kent.jackson@standardspeaker.com

Three concrete pools stand empty in a clearing outside Sheppton, but before the year ends, they will be filled with limestone that will restore life to the tainted waters of the Catawissa Creek, Jim Gotta said.

The treatment system that Gotta volunteered to help es-tablish near the outfall of the Audenreid Tunnel is a larger version of a system that al-ready cleanses water at the Oneida No. 1 Tunnel in the Eagle Rock development.

"That’s why we’re confident this will work,’’ Gotta said.

He and other volunteers with the Catawissa Creek Restoration Association began seeking money to treat mine water exiting the Audenreid Tunnel four years ago.

Their efforts helped pull in nearly $2 million and draw to-gether engineers, scientists, government workers and landowners.

People interested in the Catawissa Creek on Wednes-day afternoon checked prog-ress of the project that Gotta said will start treating water by November.

He described the project and pointed out features on a model that he built before walking the site with his lis-teners. They included repre-sentatives from the state De-partment of Environmental Resources, the Schuylkill County Conservation District, the U.S. Environmental Pro-tection Agency, Trout Unlim-ited and the Eastern Pennsyl-vania Coalition for Abandoned Mine Reclamation.

Water from the mouth of the tunnel will flow through three pipes beneath a road to the concrete pools.

Limestone in the tanks will neutralize the acidic water, causing the aluminum ions to form aluminum hydroxide. Aluminum will stick to the limestone, rendering it inert, so engineer Kim Weaver said she designed a way to flush enough water out of the pools to fill two tanker trucks per minute.

"It’s going to come whooshing out and hopefully take the aluminum with it,’’

said Weaver, of Hedin Envi-ronmental in Pittsburgh. "Aluminum is the killer.

It’s very toxic to fish.’’

Removing aluminum should allow trout and the in-sects they feed upon to live in the Catawissa again.

"Schuylkill County is going to have some of the best places to fish in the state,’’ Craig Morgan of the Schuylkill County Conservation District said of the Catawissa, which he called one of the state’s most beautiful streams.

The system will treat up to 8,500 gallons per minute, the average flow from the tunnel and the amount that can pass through holes in a partition at the intake.

If the volume exceeds that rate, excess water will flow to a diversion chamber and re-enter the creek downstream where the treated water will help neutralize it.

The squared timbers that once outlined the opening of the tunnel have collapsed, leaving a few wooden pylons at the base of a steep, eroded hillside.

James T. O’Hara, the gen-eral contractor, burrowed into the hillside with pipes to en-sure future subsidence won’t stop the flow. He heaped clamshell-size stone atop the intake to stop leaves from clogging it.

While excavating the pipe-line trenches, he separated rock that he used to control erosion.

The pipeline passes where a tributary merges with the Catawissa.

Trout fingerlings live in the tributary. They won’t swim into the main stream, but they will after treatment begins.

"As the aluminum gets out, they will come back right away. You don’t have to stock it,’’ Craig Morgan of the Con-servation District said.

Researchers from Blooms-burg University and a biologist from the Susquehanna River Basin Commission are taking an inventory of the insects in the creek and tributaries near the treatment system. Their findings will provide a basis to compare life in the stream af-ter the system starts operating.

The system is the most ex-pensive passive treatment plant in the state, Tom Davi-dock of the Conservation Dis-trict said. It won federal funds because of the persistence of groups like the Catawissa Creek Restoration Association and the project’s potential to bring life to 36 miles of the creek.

Outfall from the tunnel is such a large source of alumi-num that treating it should also help neutralize other sources of pollution, such as the Green Mountain Tunnel.

The Green Mountain Tun-nel discharges perhaps a half-mile downstream from the concrete pools.

While the water quality is poor, its flow isn’t as rapid as the discharge from the Auden-reid Tunnel, Robert Hughes of the Eastern Pennsylvania Coalition said.

The Green Mountain tunnel water meanders into the Catawissa Creek after flowing through a wetlands that Hughes studied.

He said the four-acre wet-land offers a home to blue-winged teals, red-winged black birds, bayberries, blue-berries, and hemlock, pine, and tupelo trees.

Wednesday, September 07, 2005

Tuesday, September 06, 2005

Friday, September 02, 2005

AUDENREID CONTACT INFORMATION

For questions or comments regarding the Audenreid project, please contact:

Tom Davidock

Schuylkill Conservation District

1206 Ag Center Drive

Pottsville, PA 17901

(570) 622-3742 ext. 120

fax (570) 622-4009

tdavidock@co.schuylkill.pa.us

Thursday, September 01, 2005

The forms have been taken off of Tank 3. It will be ready to be backfilled in a week.

Posted by Picasa